Plastics

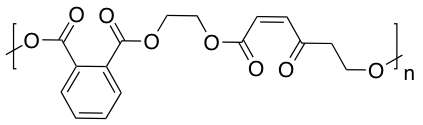

Unsaturated polyester (UP)

General information

Description

Unsaturated polyester (UP) is a thermoset that (just like epoxy) is made with two components: liquid polyester resin dissolved in styrene and a hardener. Upon mixing the two components, they will cure to form a hard plastic. Liquid UP resin is toxic (styrene) and inflammable; personal protection is required. Colourants and glitter can be added to the liquid resin. Costs and use of UP are similar to epoxy. It is a hard, cold material that can be transparent and coloured. Transparent polyesters yellow rapidly. UP produced a clear and high sound when tapped upon.History

Unsaturated polyester (UP) has been known since 1936 and is being sold since the 1940s.Production, Application, Appearance

UP can be reinforced with glass fibre to produce glass fibre reinforced polyester (GRP) which is used in automotive, aviation, and ship building industries and for the production of bathroom equipment. Polyester is also reinforced with carbon fibre, which is applied in aviation and ship building and for example in racing bicycles and bowling balls. UP shares many applications with epoxy, but it is not used for inexpensive consumer goods. In museums polyesters can be found in sculptures, design furniture, and cast objects. Also here it is often difficult to distinguish polyester and epoxy. Polyesters are a bit less expensive and are therefore more often used by artists.Properties

Material properties

ThermosetDensity: 1.1-1.12 g/cm3

Melting point: 90-245°C

Glass transition temperature: -61°C (before curing); 94-125°C (after curing)

Identification properties

Cell structure (foam): not applicableSmell: styrene-like odour

Touch: no characteristic feeling

Sound: Rigid = clear (and high pitch)

UV-radiation (when clear): fluoresces green/yellow (but is often slightly yellow already)

Polarizing filters (for clear): does (not) produce a (colour) pattern

Degradation

Process

Photo-oxidation, soiling (electrostatic).Details

UP is not considered a problem plastic.Symptoms

Discolouration - yellowing (can be influenced by the production process), loss of mechanical properties, especially decrease of bending strength.Susceptibility

UV-radiation: High (radiation in the 320-350 nm range causes strong yellowing)Light: High

Oxygen/Ozone: Low

Temp: Low

RH: High

If components are mixed in the wrong proportions the surface can be or become tacky.

Preventive conservation

Recommendations

UV-RADIATION: keep below 10 µW/lm Exclude UV with filters or no-UV light sourceLIGHT: 1 slight change in approx. 1 Mlx.h Limit light dose by reducing intensity and exposure time

OXYGEN / OZONE: ambient conditions

TEMP: common indoor conditions 10-30°C

RH: common indoor conditions 30-70% RH fluctuations: keep constant - setpoint ±5%"