Plastics

Polycarbonate (PC)

General information

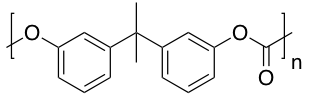

Description

Polycarbonate (PC) is clear transparent but can also be coloured. It has a high impact resistance and is used as bullet-proof glass. It blocks UV radiation but turns yellow quite rapidly hence the addition of stabilizers and anti-oxidants. It does not fluoresce under UV. Between polarizing filters it produces bright colours. It resembles PMMA, which may have a higher gloss though. Due to its good properties it is a relatively expensive plastic which is used less frequently by artists.History

PC was patented in 1953 and has been produced industrially since 1958.Production, Application, Appearance

Due to the high impact resistance, heat resistance, dimensional stability, and good electrical insulation properties PC is used widely for technical applications. PC sheet is an unbreakable alternative for glass and is used in protective eye glasses, helmets and shields, CDs and DVDs, as casing for equipment and in furniture.Properties

Material properties

ThermoplasticDensity: Rigid = 1.19-1.22 g/cm3

Melting point: 255-267°C

Glass transition temperature: calc.=134-158°C; exp.=137-154°C

Identification properties

Cell structure (foam): not applicableSmell: no characteritic smell

Touch: no characteristic touch

Sound: Rigid = no characteristic sound; Film = no characteristic sound

UV-radiation (when clear): does not fluoresce

Polarizing filters (for clear CE): produces bright colours

Degradation

Process

Photo-oxidation; soiling (electrostatic).Details

None.Symptoms

Yellowing, surface becomes matte, loss of mechanical properties resulting in chipping, fractures and tears.Susceptibility

UV-radiation: LowLight: Low

Oxygen/Ozone: Low

Temp: High - becomes brittle at low temperatures

RH: High - fluctuating RH

Preventive conservation

Recommendations

UV-RADIATION: avoid extremesLIGHT: 1 slight change in approx. 300 Mlx.h Avoid high light dose

OXYGEN / OZONE: ambient conditions

TEMP: common indoor conditions 10-30°C

RH: setpoint 30-70% RH fluctuations: keep constant - setpoint ±5%

Other names

- Makrolon

- Lexan

- Merlon

- Kanaalplaat