Plastics

Ethylene Vinyl Acetate (EVA)

General information

Description

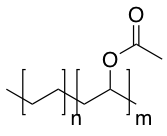

Ethylene Vinyl Acetate (EVA) is a co-polymer of polyethylene (PE) and vinyl acetate. The material is more expensive than PE and therefore is used for high-quality products, not for disposables. EVA is a thermoplast, the vinyl acetate gives EVA elastic properties. The more vinyl acetate, the more elastic. Hence it is considered an elastomer. EVA consists of 60-90% polyethylene and therefore has much in common with PE. It is a flexible and soft material that can have many colours. EVA feels like velvet.History

EVA is commercially available since 1960.Production, Application, Appearance

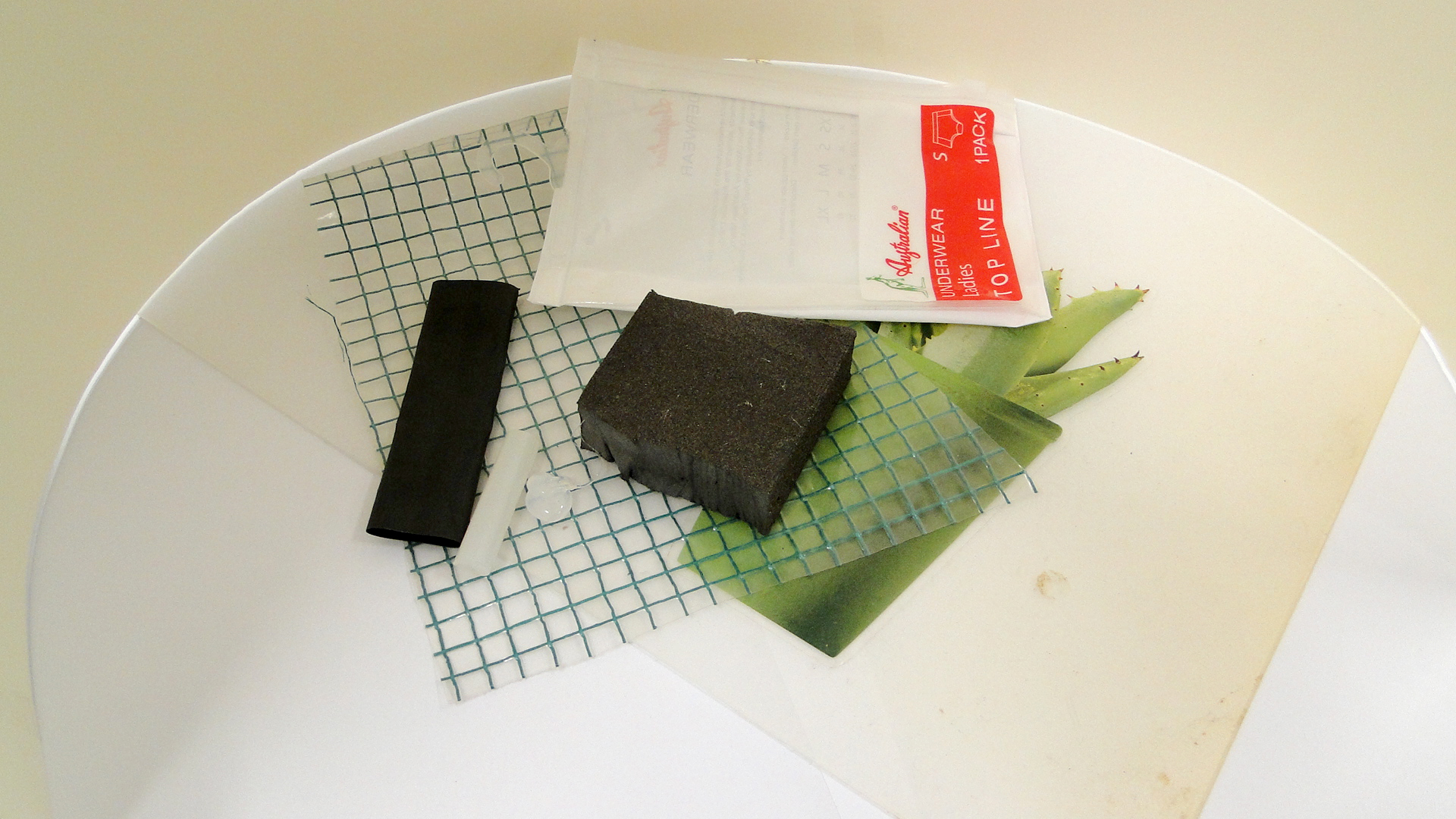

EVA elastomer can be injection moulded and produced as foam and film. EVA film is elastic and can be transparant. EVA foam shows an interesting behaviour: it pops out of the mould because the material expands 170% after manufacture. EVA is suitable for indoor and outdoor application. It is used for example for babyseats, shoe soles, solar panels, food wrapping films, toys, yoga mats, solid tyres for prams and shock-absorbing sportsware.Properties

Material properties

ThermoplasticDensity: 0.92-0.98 g/cm3; schuim: g/cm3

Melting point: 58-112°C

Glass transition temperature: -38 to -42°C

Identification properties

Cell structure (foam): closedSmell: no characteristic smell

Touch: velvety

Sound: no characteristic sound

UV-radiation (when clear): fluoresces bright blue

Polarizing filters (for clear EVA): does not produce a colour pattern

Degradation

Process

Photo-oxidationDetails

noneSymptoms

Yellowing, surface turns matte, loss of mechanical properties resulting in tears and fractures.Susceptibility

UV-radiation: MediumLight: Medium

Oxygen/Ozone: Low

Temp: High

RH: Medium

Preventive conservation

Recommendations

UV-RADIATION: keep below 75 µW/lm UV filter for daylight and fluorescent light - reduce intensityLIGHT: 1 just noticeable change in approx. 30 Mlx.h Moderate light dose. Control intensity and exposure time

OXYGEN / OZONE: ambient conditions

TEMP: keep under 15°C. At higher temperatures it becomes more sensitive to deformation

RH: common museum conditions 40-60% RH fluctuations: setpoint ±10% or ±5% when allowing seasonal fluctations between 35-65%